Introduction

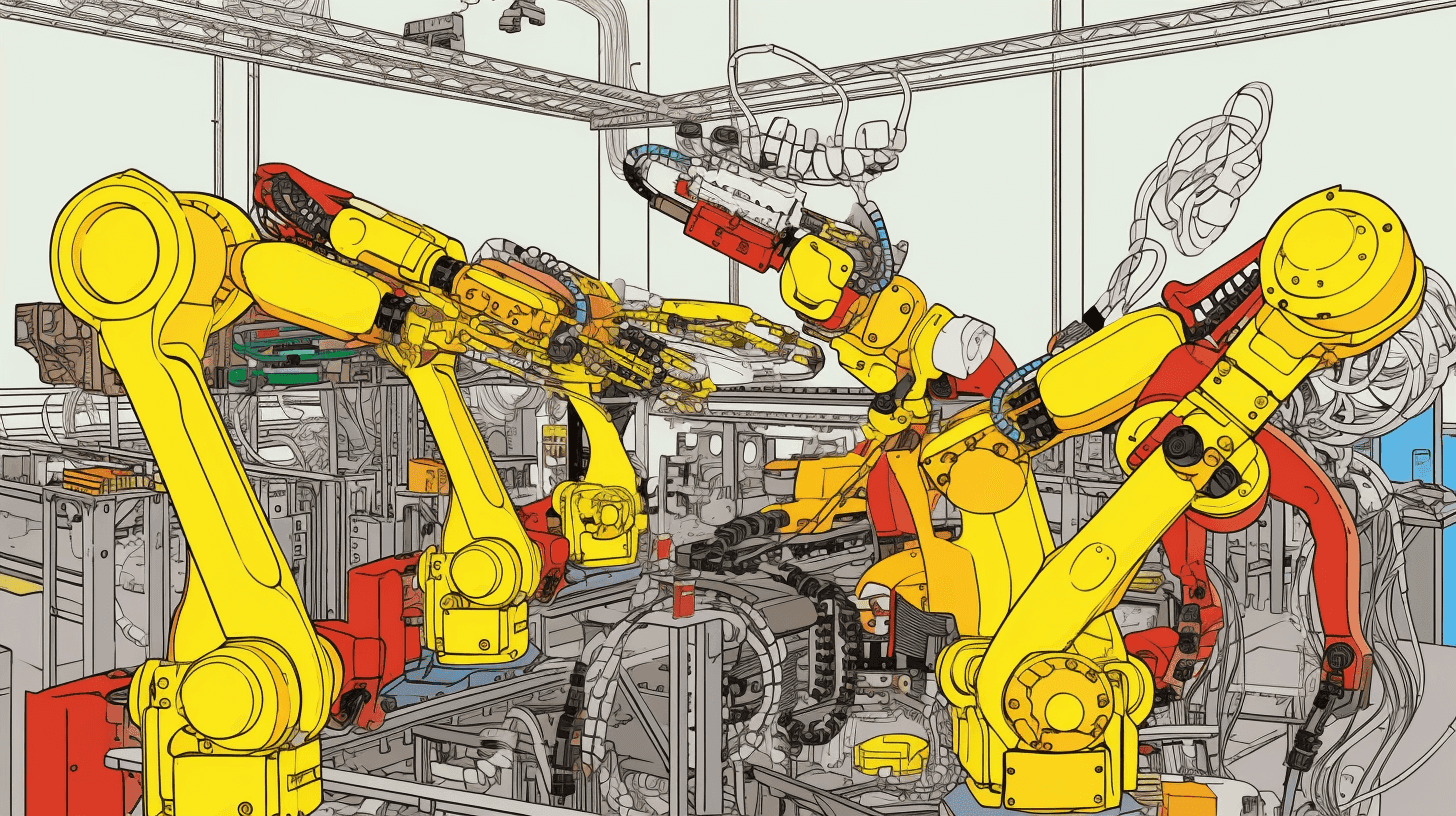

Industrial automation and robotics play a critical role in modern manufacturing, enabling companies to streamline their processes, improve product quality, and increase overall efficiency. As a leader in this field, FANUC Robotics offers a wide range of robotic and automation solutions designed to meet the diverse needs of various industries. In this comprehensive article, we will explore the history, products, applications, and industries served by FANUC Robotics, as well as how they compare to competitors and their commitment to training and support.

1. History of FANUC Robotics

Origins of the Company

FANUC Robotics was founded in 1956 as a subsidiary of Fujitsu, focusing on the development and production of numerical control (NC) equipment. Over time, the company expanded its offerings to include computer numerical control (CNC) systems, servo motors, and eventually industrial robots.

Evolution of the Company's Product Offerings and Market Presence

FANUC Robotics has continuously evolved its product offerings and market presence over the years, becoming a global leader in the industrial automation sector. Today, FANUC operates in over 100 countries, with more than 4,000 employees and over 20 million CNC systems and robots installed worldwide.

Key Milestones and Achievements

Some of the key milestones and achievements in FANUC Robotics' history include:

- Introduction of their first industrial robot in 1974

- Development of the first electric injection molding machine (ROBOSHOT) in 1984

- Launch of the first collaborative robot (COBOT) in 2015

2. FANUC's Product Portfolio

Industrial Robots

FANUC offers a wide range of industrial robots, including articulated, delta, SCARA, and more. These robots are designed for various applications, such as material handling, welding, and assembly.

Collaborative Robots (COBOTs)

FANUC's collaborative robots, also known as COBOTs, are designed to work alongside human operators in shared workspaces, enhancing productivity and efficiency.

RoboDrills and RoboCuts (CNC Machines)

FANUC's RoboDrills and RoboCuts are high-performance CNC machines used for drilling, milling, and cutting applications in various industries.

RoboShots (Injection Molding Machines)

The FANUC RoboShot series consists of advanced electric injection molding machines designed to provide precise and reliable performance in plastic injection molding processes.

R-30iB and R-30iB Plus Robot Controllers

FANUC's R-30iB and R-30iB Plus robot controllers are designed to provide seamless integration and control for FANUC's industrial robots, offering advanced features and capabilities.

Intelligent Features

FANUC Robotics offers a range of intelligent features for its robots, such as iRVision (robotic vision system), Force Sensing (robotic force control), and more, enabling enhanced functionality and performance.

3. FANUC's Robotic Applications

FANUC's robots are designed for various applications, including:

Material Handling

Material handling robots are used for tasks such as picking, placing, and transporting items within production environments.

Welding

FANUC's welding robots are designed for applications like arc welding, spot welding, and laser welding, offering high precision and efficiency.

Assembly

Assembly robots are used to assemble components in various manufacturing processes, enhancing speed and accuracy.

Painting

FANUC's painting robots provide consistent, high-quality paint application in automotive, aerospace, and other industries.

Palletizing

Palletizing robots are designed to stack and unstack items on pallets for transportation and storage, increasing efficiency and reducing manual labor.

Packaging

Packaging robots are used to package products in various industries, streamlining the packaging process and improving productivity.

Machine Tending

Machine tending robots are designed to load and unload machines, such as CNC machines and injection molding machines, reducing downtime and increasing throughput.

Inspection

Inspection robots can perform quality control checks on products, ensuring that they meet the required specifications and standards.

Dispensing

Dispensing robots are used for applications such as adhesive and sealant dispensing, providing precise and consistent application.

4. Industries Served by FANUC Robotics

FANUC Robotics serves a wide range of industries, including:

Automotive

In the automotive industry, FANUC's robots are used for tasks such as welding, painting, and assembly.

Aerospace

FANUC's robots are employed in aerospace manufacturing for processes like drilling, riveting, and inspection.

Consumer Goods

Consumer goods manufacturers use FANUC's robots for tasks like packaging, palletizing, and assembly.

Electronics

Electronics manufacturers utilize FANUC's robots for processes like assembly, soldering, and inspection.

Food and Beverage

In the food and beverage industry, FANUC's robots are used for tasks such as packaging, palletizing, and inspection.

Medical Devices

Medical device manufacturers use FANUC's robots for tasks like assembly, packaging, and quality control.

Metal Fabrication

FANUC's robots are used in metal fabrication processes such as welding, cutting, and bending.

Plastics

In the plastics industry, FANUC's robots are used for tasks like injection molding, assembly, and packaging.

Pharmaceuticals

Pharmaceutical manufacturers use FANUC's robots for tasks like packaging, inspection, and material handling.

5. FANUC Robotics vs. Competitors

Comparison with Other Major Robotics Brands

FANUC Robotics faces competition from other major robotics brands, such as ABB, KUKA, Yaskawa Motoman, and more. Each brand offers its unique strengths and weaknesses, with FANUC being known for its reliability, extensive product range, and innovative features.

Market Share and Global Presence

FANUC Robotics holds a significant market share in the industrial automation sector, with a strong global presence across more than 100 countries.

6. FANUC's Commitment to Training and Support

FANUC Academy

FANUC offers the FANUC Academy, providing training courses and certification programs for operators, programmers, and maintenance personnel.

Training Courses and Certification Programs

FANUC's training courses and certification programs cover topics like robot programming, maintenance, and system integration, ensuring that users are well-equipped to manage and operate FANUC robots.

FANUC Authorized System Integrators (ASI) Network

FANUC's Authorized System Integrators (ASI) network consists of experienced companies that provide integration services for FANUC robots, ensuring seamless implementation and support.

Customer Support Services

FANUC offers comprehensive customer support services, including technical support, spare parts, and maintenance services, ensuring the optimal performance and longevity of their products.

7. The Future of FANUC Robotics

Investments in Research and Development

FANUC continues to invest in research and development, driving innovation and introducing new products and features to the market.

Industry 4.0 and IoT Integration

FANUC is actively working on integrating Industry 4.0 and IoT technologies into their products, enabling greater connectivity and data-driven decision-making.

Expanding Product Offerings and Capabilities

FANUC aims to expand its product offerings and capabilities, further strengthening its position as a leader in the industrial automation sector and meeting the evolving needs of its customers.

FANUC Robotics has established itself as a global leader in the industrial automation sector, providing a wide range of robotic and automation solutions to various industries. With a history of innovation and a commitment to training and support, FANUC continues to shape the future of industrial automation. As the demand for robotics and automation solutions grows, FANUC is well-positioned to remain at the forefront of the industry, offering reliable, cutting-edge products and services that meet the evolving needs of manufacturers worldwide.