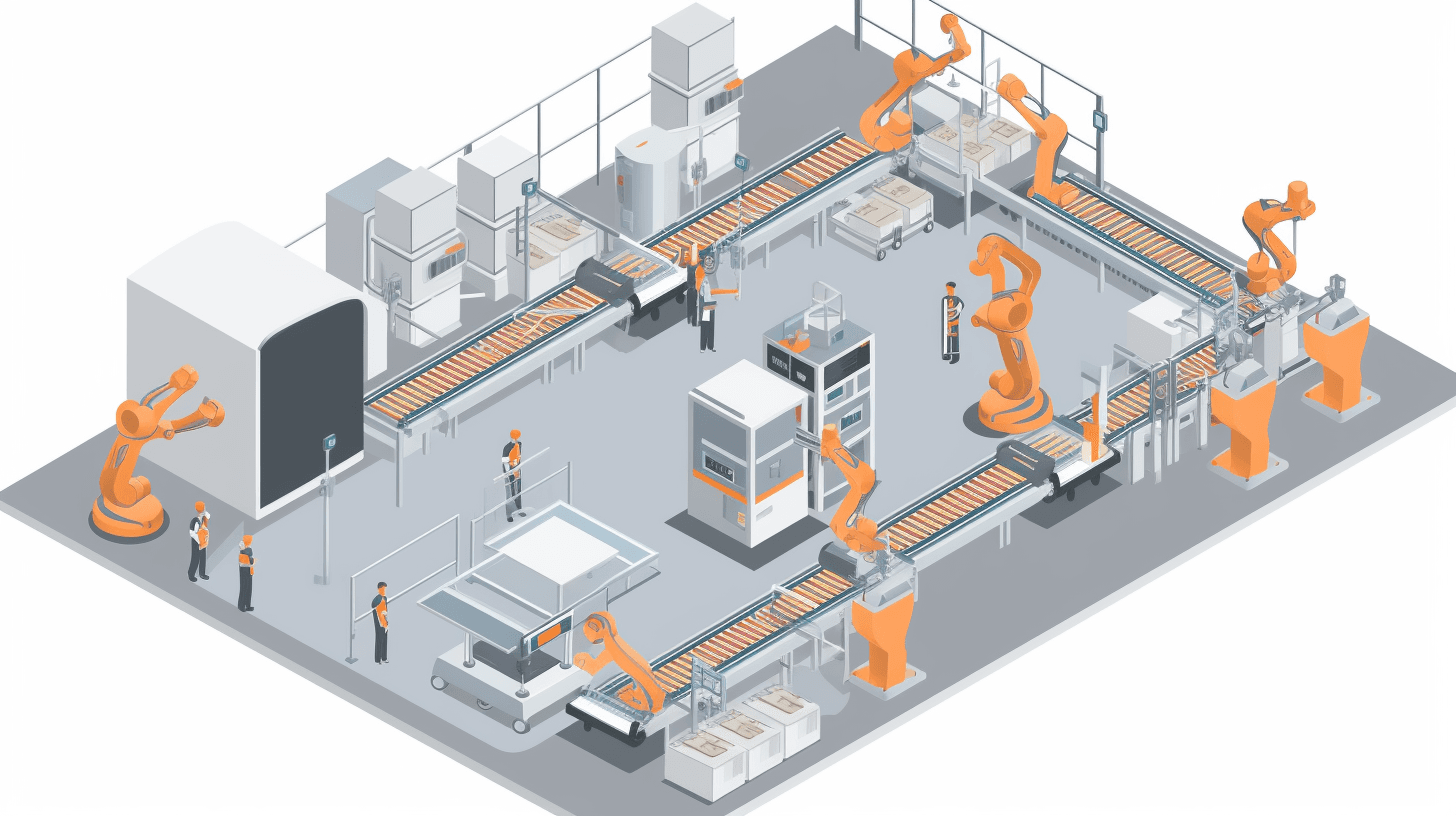

In recent years, the importance of industrial robots in manufacturing and automation has grown exponentially. These advanced machines are transforming the way businesses operate, streamlining processes, and increasing overall efficiency. As companies consider adopting industrial robots, understanding the Return on Investment (ROI) becomes crucial in making informed decisions.

ROI is a financial metric that evaluates the profitability of an investment by comparing the net profit gained to the initial investment cost. In the context of industrial robots, the central question to be addressed is: What is the ROI for industrial robots, and how do you calculate it?

In this guide, we will delve into the factors that influence ROI for industrial robots, such as labor savings, productivity improvements, and quality enhancements. We will also explore the methods used to calculate ROI, taking into account factors like the robot's cost, installation, training, maintenance, and energy consumption.

Furthermore, we will examine case studies and examples of ROI for industrial robots across various industries, such as automotive, electronics manufacturing, food and beverage production, pharmaceutical, and warehousing and logistics. This will provide a comprehensive understanding of the real-world implications of industrial robot ROI.

Finally, in the conclusion, we will summarize the key points and reinforce the importance of understanding ROI for industrial robots. By examining the factors that influence ROI and the methods used to calculate it, businesses can make well-informed decisions about adopting industrial robots and maximizing their investment.

Factors influencing ROI for industrial robots

-

Labor savings: Industrial robots can reduce labor costs by automating repetitive tasks and working round-the-clock. This not only frees up employees for higher-value tasks but also reduces the need for overtime pay and additional hiring.

-

Productivity improvements: Robots can work faster and more consistently than human workers, leading to increased output and better utilization of production resources.

-

Quality enhancements: Industrial robots are known for their precision and accuracy, which can result in fewer defects and improved product quality. This reduces the need for rework, saving both time and money.

-

Reduction in waste and rework: By minimizing errors and maintaining consistent performance, robots can help cut down on waste and rework, thus lowering production costs.

-

Flexibility and scalability: Robots can be easily reprogrammed and redeployed for different tasks, providing businesses with the flexibility to adapt to changing market conditions and scale production as needed.

Methods to calculate ROI for industrial robots

-

Basic formula: ROI = (Net Profit / Investment Cost) x 100. This simple formula provides a general idea of the profitability of an investment in industrial robots.

-

When calculating ROI, consider factors like the robot's cost, installation, training, maintenance, and energy consumption. These costs should be weighed against the potential benefits, such as labor savings, productivity improvements, and quality enhancements.

-

It's also important to compare the ROI of various robot types and manufacturers to make the best decision for your specific application.

Case studies/examples of ROI for industrial robots

-

Automotive industry: In the automotive sector, robots have been widely adopted for tasks like welding, painting, and assembly. Companies have reported significant labor savings, reduced downtime, and improved product quality, leading to a favorable ROI.

-

Electronics manufacturing: Robots are used in electronics manufacturing for tasks like pick-and-place, soldering, and testing. These applications have resulted in increased productivity, better product quality, and a positive ROI.

-

Food and beverage production: In the food and beverage industry, robots can be found handling tasks like packaging, palletizing, and quality inspection. They have helped improve efficiency, reduce waste, and maintain consistent product quality, contributing to a strong ROI.

-

Pharmaceutical and medical device manufacturing: Industrial robots are used for tasks like drug dispensing, assembly, and packaging in pharmaceutical and medical device manufacturing. Robots have been able to improve product quality, reduce contamination risks, and increase overall efficiency, yielding a favorable ROI.

-

Warehousing and logistics: Robots are increasingly being used in warehousing and logistics for tasks like sorting, picking, and packing. They have helped streamline operations, reduce errors, and minimize labor costs, leading to an attractive ROI.

In conclusion, understanding the Return on Investment (ROI) for industrial robots is essential for businesses considering their implementation. By examining the factors that influence ROI, such as labor savings, productivity improvements, quality enhancements, and reduction in waste and rework, decision-makers can make well-informed choices about adopting industrial robots.

We have also explored the methods used to calculate ROI, taking into account factors like the robot's cost, installation, training, maintenance, and energy consumption. By comparing the ROI of various robot types and manufacturers, businesses can optimize their investment in automation.

The case studies and examples discussed in this guide demonstrate that investing in industrial robots can lead to significant long-term benefits across various industries, such as automotive, electronics manufacturing, food and beverage production, pharmaceutical, and warehousing and logistics. However, it's important to remember that each business's ROI will vary based on its unique circumstances and goals.

In order to make the most of an investment in industrial robots, businesses should conduct a thorough analysis of the potential ROI for their specific industry and application. By doing so, they can capitalize on the many advantages that industrial robots offer, such as increased productivity, efficiency, and quality, ultimately leading to a favorable ROI and long-term success.