The rapid rise of industrial automation has led to the widespread adoption of industrial robots in various sectors. These robots play a crucial role in streamlining production processes, improving efficiency, and enhancing product quality. One of the key components of an industrial automation system is the industrial robot cell. In this comprehensive guide, we will explore the concept of industrial robot cells, their design and implementation, and the numerous benefits they offer to businesses.

What is an Industrial Robot Cell?

Definition of an Industrial Robot Cell

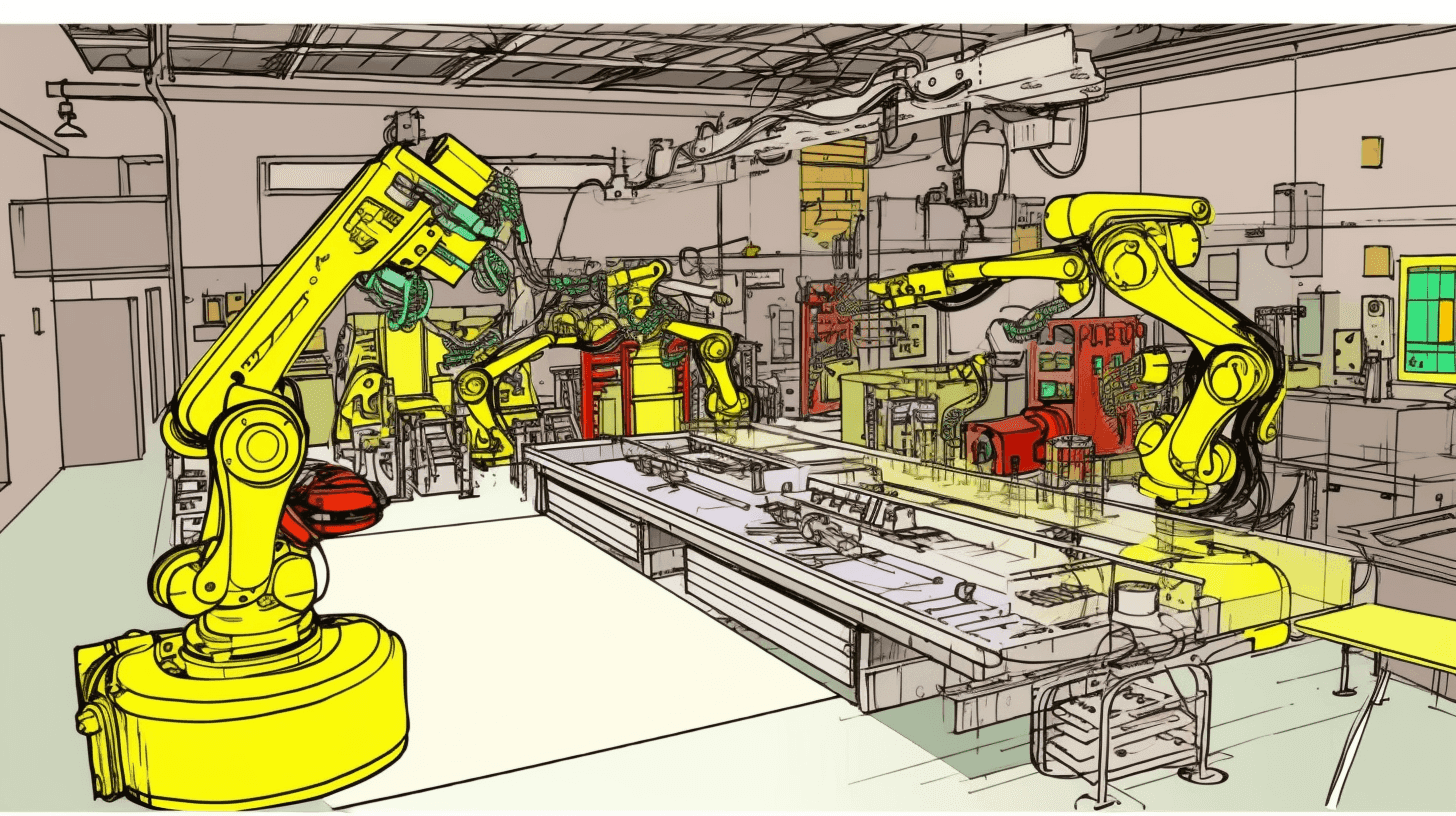

An industrial robot cell is a self-contained, integrated system that houses one or more robots, along with the necessary equipment and safety measures, designed to perform specific tasks within a manufacturing or production environment.

Components of a Typical Robot Cell

A typical industrial robot cell may consist of the following components:

- Industrial robot(s)

- End-of-arm tooling (EOAT)

- Workpiece fixtures or conveyors

- Safety equipment (e.g., light curtains, safety barriers)

- Control systems and user interfaces

Types of Industrial Robot Cells

There are various types of industrial robot cells, designed for different applications, such as:

- Welding robot cells

- Assembly robot cells

- Painting robot cells

- Inspection robot cells

Key Elements of Industrial Robot Cell Design

Assessing Needs and Objectives

Before designing an industrial robot cell, it is essential to assess the specific needs and objectives of the project. This involves identifying the tasks that the robot cell will perform, the production volume, and the desired level of automation.

Workspace and Layout Considerations

The workspace and layout of an industrial robot cell must be carefully planned to ensure smooth operation and efficient use of space. This includes determining the optimal placement of the robot(s), equipment, and safety measures.

Robot Selection and Integration

Selecting the right robot(s) for the cell is crucial, as it will determine the efficiency and effectiveness of the system. Factors to consider include the robot's payload capacity, reach, speed, and compatibility with the required EOAT.

End-of-Arm Tooling (EOAT) Selection

The EOAT is the device attached to the end of a robot's arm that enables it to perform specific tasks. The choice of EOAT will depend on the application, and may include grippers, welding torches, paint guns, or inspection cameras.

Safety and Risk Assessment

Ensuring the safety of workers and equipment is a top priority when designing an industrial robot cell. This involves conducting a thorough risk assessment and implementing appropriate safety measures, such as safety barriers, light curtains, and emergency stop systems.

Human-Robot Interaction

Designing an industrial robot cell should also consider the degree of human-robot interaction required, which may range from fully automated systems to collaborative robots that work alongside human operators.

Steps to Implement an Industrial Robot Cell

Planning and Consultation

The first step in implementing an industrial robot cell is to engage in planning and consultation with stakeholders, including management, operators, and engineering staff. This will help to identify needs, objectives, and potential challenges.

Design and Engineering

Once the planning phase is complete, the design and engineering stage involves developing detailed drawings, specifications, and control systems for the robot cell.

Simulation and Testing

Before installation, it is essential to simulate and test the robot cell, ensuring that all components function correctly and safely, and that the system meets the desired performance criteria.

Installation and Integration

The installation and integration process involves assembling the robot cell components, integrating them with existing production equipment, and connecting them to the control systems.

Training and Support

Operators and maintenance staff will require training in the operation, programming, and maintenanceof the robot cell. Providing ongoing support and resources is crucial for the successful implementation and operation of the system.

Maintenance and Optimization

Regular maintenance and optimization of the robot cell will ensure optimal performance, prolong the lifespan of the equipment, and minimize downtime.

4. Major Industrial Robot Brands for Robot Cells

When selecting a robot for your industrial robot cell, it's essential to consider reputable and reliable brands, such as:

- ABB

- KUKA Robotics

- FANUC Corporation

- Yaskawa Motoman

- Kawasaki Robotics

- Universal Robots (Teradyne)

- Stäubli Robotics

- Omron

Benefits of Implementing Industrial Robot Cells

There are several key benefits to implementing industrial robot cells in your production process:

Increased Productivity and Efficiency

Industrial robot cells can significantly increase productivity and efficiency by automating repetitive tasks and operating at high speeds with consistent performance.

Improved Precision and Quality

Robotic systems offer a high level of precision and accuracy, resulting in improved product quality and reduced waste due to errors or inconsistencies.

Enhanced Safety and Reduced Risks

By automating potentially hazardous tasks, industrial robot cells can enhance safety for workers and reduce the risk of accidents and injuries.

Flexibility and Scalability

Industrial robot cells can be easily reprogrammed or reconfigured to adapt to changing production requirements, offering flexibility and scalability for businesses.

Cost Savings

By automating labor-intensive tasks and reducing waste, industrial robot cells can lead to significant cost savings in the long run.

Challenges and Considerations for Adopting Industrial Robot Cells

While there are many benefits to adopting industrial robot cells, there are also some challenges and considerations to keep in mind:

Initial Investment and Cost-Benefit Analysis

Implementing an industrial robot cell can require a significant initial investment. Conducting a thorough cost-benefit analysis can help determine the potential return on investment and ensure the project's financial viability.

Integration with Existing Processes and Systems

Integrating an industrial robot cell with existing production processes and equipment may require modifications or upgrades. Planning for these changes and ensuring a smooth transition is essential.

Training and Skills Development

Workers will need training and skills development to effectively manage and operate industrial robot cells. Allocating time and resources for this training is crucial for successful implementation.

Maintenance and Support

Industrial robot cells require ongoing maintenance and support to ensure optimal performance and longevity. Choosing a manufacturer that offers reliable technical support and maintenance services is essential.

Adapting to Future Needs and Technological Advancements

As technology continues to evolve, it's crucial to select industrial robot cells that can be upgraded or adapted to meet future needs and remain competitive in the market.

Industrial robot cells have the potential to revolutionize modern manufacturing by offering increased productivity, improved quality, and enhanced safety. By understanding the key elements of robot cell design, implementation, and the benefits they offer, businesses can make informed decisions about incorporating this technology into their production processes. As the demand for automation and efficiency continues to grow, industrial robot cells will play an increasingly important role in shaping the future of manufacturing.