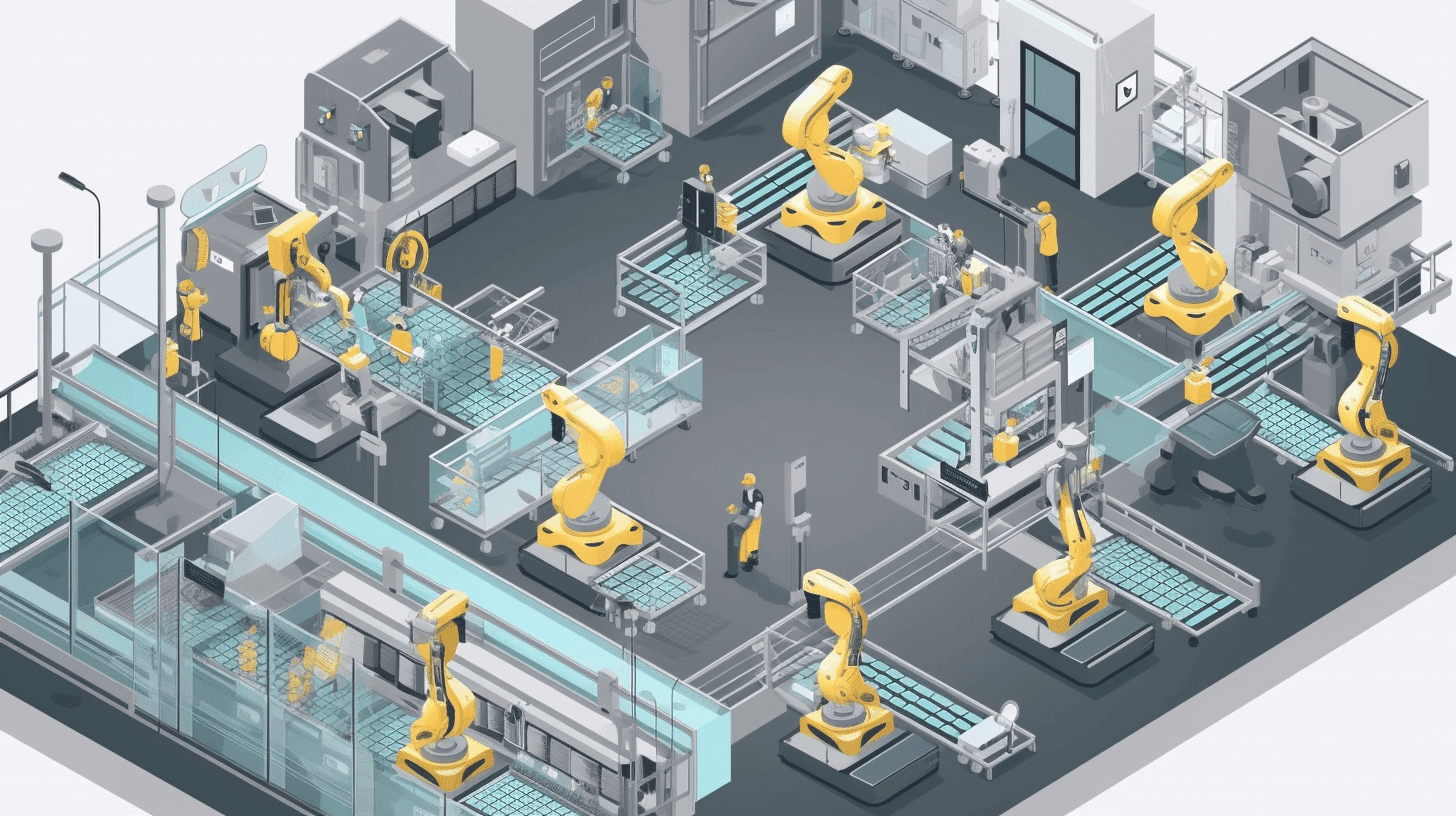

As we step into a new era of automation, industrial robots have become an essential component in the manufacturing landscape. From assembly lines to packing stations, these mechanical marvels are revolutionizing the way we produce goods and services, driving efficiency and productivity to new heights.

In industries ranging from automotive to electronics, industrial robots have become increasingly popular as companies seek to automate processes, reduce labor costs, and improve product quality. This brings us to an important question: how much do industrial robots cost?

In this article, we'll explore the various factors that influence the cost of industrial robots and provide cost estimates for different types of robots and applications. By understanding these factors, you'll be better equipped to make an informed decision when considering an investment in robotic technology.

Additionally, we'll delve into the long-term cost considerations associated with adopting industrial robots, such as installation, maintenance, and energy consumption. By the end of this article, you'll have a clearer picture of the costs involved in implementing industrial robotic solutions and the potential return on investment they can offer.

Factors influencing the cost of industrial robots

When considering the cost of industrial robots, there are several factors that come into play, including:

- Robot type: Articulated, SCARA, delta, and cartesian robots are some common types, each with different price points.

- Payload capacity: The ability to handle heavier loads typically increases the cost.

- Reach: The distance a robot can extend its arm impacts the price.

- Speed: Faster robots often come with higher price tags.

- Control system complexity: More advanced control systems can raise the cost.

Additionally, the choice of manufacturer can also impact the price, with some brands offering more competitive pricing than others.

Examples of cost estimates for various types of industrial robots

To give you a better idea of the costs involved, let's look at some examples of cost estimates for different types of robots from various manufacturers:

Articulated Robots

- ABB: $25,000 - $75,000

- KUKA Robotics: $30,000 - $80,000

- FANUC Corporation: $40,000 - $100,000

SCARA Robots

- Epson Robots: $10,000 - $30,000

- Denso Robotics: $20,000 - $40,000

- Mitsubishi Electric: $15,000 - $45,000

Delta Robots

- Stäubli Robotics: $40,000 - $70,000

- Omron: $30,000 - $60,000

- Nachi Fujikoshi: $35,000 - $55,000

Additional costs for a complete robotic system

It's important to note that the robot itself is only part of the total cost of an industrial robotic system. Additional costs you need to consider include:

- End-of-arm tooling (EOAT): Customized grippers, suction cups, or other tools attached to the robot arm.

- Integration: Incorporating the robot into your existing manufacturing process.

- Installation: Setting up the robot and making sure it's running correctly.

- Training: Ensuring your staff knows how to operate and maintain the robot.

Long-term cost considerations

When investing in industrial robots, it's essential to keep long-term costs in mind, such as:

- Maintenance: Regular upkeep to ensure the robot remains operational and efficient.

- Energy consumption: The cost of powering the robot during its operation.

- Software updates: Keeping the robot's software up-to-date to maintain peak performance.

By understanding these long-term costs and the potential return on investment (ROI) for adopting industrial robots, you can make a more informed decision when considering the implementation of robotic solutions in your business.

In conclusion, the cost of industrial robots can vary significantly depending on factors such as robot type, payload capacity, reach, speed, and control system complexity. It's important to remember that the robot itself is only part of the total cost of an industrial robotic system, and additional expenses like end-of-arm tooling, integration, installation, and training should also be considered.

Long-term costs, such as maintenance, energy consumption, and software updates, should be factored into your decision-making process, along with the potential return on investment that industrial robots can offer. As you research specific robots and manufacturers based on your unique needs, you'll gain a more accurate cost estimate and a better understanding of the benefits of investing in industrial robots.

With increased efficiency, productivity, and potential for growth in various industries, embracing industrial robots can be a game-changing decision for your business. By considering the costs involved and the value they can bring, you can make a well-informed decision about implementing robotic solutions in your operations.