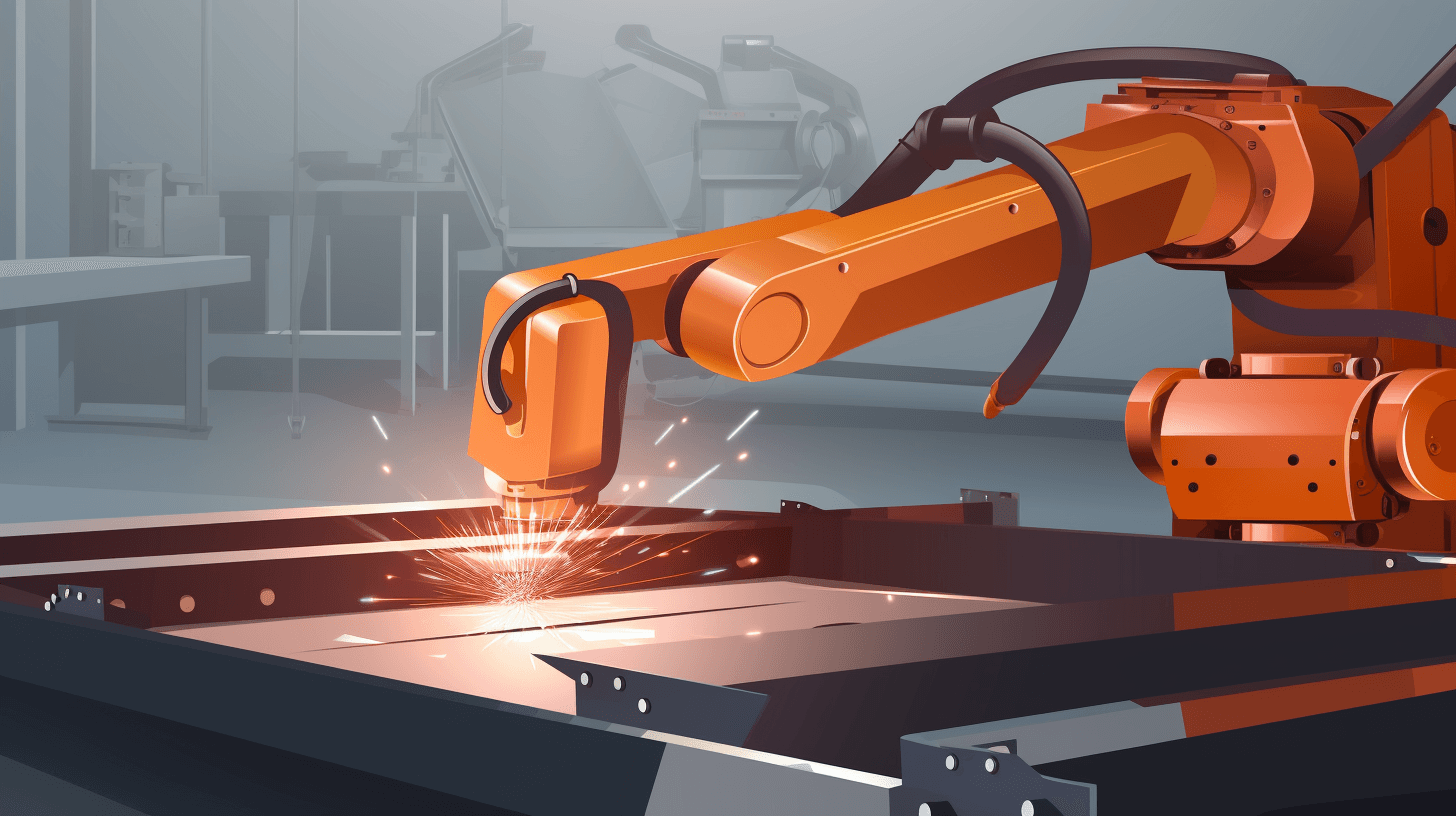

Plasma cutting has long been a vital technique in the manufacturing industry, known for its ability to cut through a variety of metals with precision and speed. With the advent of robotic technology, a new era of cutting efficiency has emerged. Robotic plasma cutters have revolutionized the way industries handle metal cutting, providing unparalleled accuracy, productivity, and safety. In this article, we'll explore the world of robotic plasma cutters, their benefits, and how they're transforming modern manufacturing.

Understanding Plasma Cutting Technology

Plasma cutting is a process that uses an accelerated jet of hot plasma to cut through electrically conductive materials, such as steel, aluminum, brass, and copper. There are two primary types of plasma cutting: manual, where an operator guides the cutting torch by hand, and mechanized, which relies on automated systems like CNC machines or robots.

Robotic Plasma Cutters: A Game Changer

The integration of robotics with plasma cutting technology has resulted in a powerful combination known as robotic plasma cutters. These advanced systems offer several significant advantages over traditional plasma cutting methods:

- Precision and accuracy: Robotic plasma cutters can achieve a high level of precision, ensuring clean and accurate cuts every time.

- Increased productivity: Automated cutting processes can work faster and more consistently than manual methods, reducing production times and increasing output.

- Enhanced safety: By minimizing the need for human interaction with cutting equipment, robotic plasma cutters help reduce the risk of workplace accidents.

- Flexibility and adaptability: Robotic systems can be easily reprogrammed to handle different cutting tasks, making them adaptable to various production requirements.

Key Features of Robotic Plasma Cutters

Robotic plasma cutters come equipped with several features that make them stand out from conventional cutting methods:

- High-definition plasma cutting system: This technology allows for extremely precise cutting with minimal dross and a narrow kerf width.

- Advanced robotic arm and motion control: A sophisticated robotic arm ensures smooth and accurate movements throughout the cutting process.

- User-friendly software and programming interface: Modern robotic plasma cutters come with intuitive software that simplifies programming and operation.

- Automatic height control and collision detection: These features help maintain the optimal cutting height and prevent damage to the equipment by detecting potential collisions.

Industries and Applications

Robotic plasma cutters are used across various industries, including:

- Metal fabrication: From custom parts to large-scale production, robotic plasma cutters are ideal for precise and efficient metal cutting.

- Automotive and aerospace: These industries demand high levels of precision and quality, making robotic plasma cutting a perfect fit.

- Shipbuilding and repair: Large-scale metal cutting is common in shipbuilding, and robotic plasma cutters can help streamline the process.

- Construction and heavy equipment manufacturing: Robotic plasma cutting systems can handle the thick and heavy materials often used in these industries.

Selecting the Right Robotic Plasma Cutter

When choosing a robotic plasma cutter, consider the following factors:

- Compatibility with existing systems: Ensure the cutter can integrate seamlessly with your current production setup.

- Payload capacity and cutting area: Make sure the cutter can handle the weight and size of the materials you work with.

- Cutting performance and consumables cost: Assess the cutter's performance in terms of cut quality and the cost of consumables like electrodes and nozzles.

- Technical support and maintenance: Opt for a manufacturer that offers reliable technical support and maintenance services.

Robotic plasma cutters have undoubtedly transformed the manufacturing landscape, offering exceptional precision, increased productivity, and enhanced safety. As industries continue to adopt this cutting-edge technology, we can expect further advancements and innovations in robotic plasma cutting.

By understanding the benefits of robotic plasma cutters and their applications across various industries, manufacturers can make informed decisions on the right cutting solutions for their needs. As the demand for higher efficiency and precision grows, robotic plasma cutters are poised to become an indispensable tool in modern manufacturing.